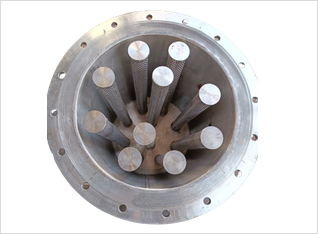

The standard candle-filters are constructed for filter-cartridges, which are double open ended (DOE), e.g. woundelements with a length from 9 3/4" up to 40" can be fitted inthe different housings Stainless steel as SS304, SS316 are available as material for the housings.

Filter Elements -PP,GFT,Wound , PTFE

Sizes -15 mm to 100 mm

End Connections -Screwed , Flanged

Housing -SS 304,SS316 , Higher alloys buffed & polished

Sealing -Food grade O rings , gasketsThese are mainly suggested for Distilled water , syrups , Brewarages , Pharma